The externally generated high voltage gun generates high voltage in a control panel. The generated high voltage will be transferred to gun tip via 5 or 10 meter long high voltage cable. The cable will release the high voltage at the gun tip. While integrated powder gun generates 100 KV in gun itself and releases it at the gun tip.

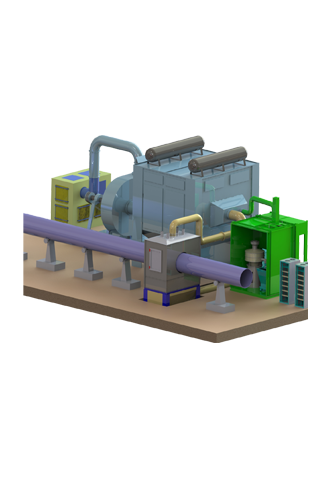

HIGH FLOW Pipe Coating Equipment to Spray Fusion Bonded Epoxy Powder (FBE) for Pipe Coating

Suitable for Single, Dual and three layer FBE coating

World’s first Integrated 100 KV epoxy powder spray gun specially designed for new generation of Fusion Bonded Epoxy Powder (FBE) coating for pipe line industry.

High Flow Epoxy Gun

Summary of Benefits:

- Higher film thickness (up to 1000Micron) with less numbers of guns

- Higher working life with lowest maintenance cost

- Lower Initial cost

- Can be used as a LOW FLOW VERSION with the standard conversion kit for regular 3 layer coating.

- Easy to use and set up, this model is suited for small panel coating as well as small production runs.

Mitsuba also offers powder spay booth with recovery system for pipe coating application.

Frequently Asked Questions

This technology has inherent limitations, drop in efficiency and frequent failures in components. Huge loss occurs while H.V gets transferred from the panel to the gun. Gun tip voltage is often less then 70 K,V.-- resulting in excess overspray.

Integrated powder gun generates 100 KV in gun itself and releases the same at the gun tip. Both, high voltage generation and use, is at the same place. There is no high voltage cable. This eliminates the loss associated with transmission of High Voltage from the panel. Complete 100 KV is available at the gun tip. This enhances transfer efficiency and reduces the powder consumption. Also since number of parts is reduced, chances of trouble are reduced.

Integrated high voltage gun has proven superior and more suitable for all types of pipe coating -- single layer, Dual Layer or three layer.

No. Conversion kit is provided, which can change the high flow gun to low flow gun and vice-versa. You can select your own combination of high flow and low flow guns.

The Performance Monitoring System: This is a high-end diagnostic system, which constantly monitors and indicates the performance of every component in the equipment. Even unskilled labor can detect and troubleshoot with ease, swiftness and precision. And thanks to the unique plug-in plug out design, the problem can be rectified immediately. In a nutshell, smart tracker ensures your system is always in a perfect working condition

More than hundred Mitsuba’s guns are working satisfactory in pipe coating industry across the world.

ENQUIRE NOW

Manual Powder Coating Equipment

Sprayright

Tribo Series - Manual

Portable Powder Coating Equipment

Automatic Powder Coating Equipment

Automatic Powder Coating Gun Movers

Powder Coating Booth & Recovery

- Powder Coating Booth with Cyclone Recovery - UNI Series

- Powder Coating Booth with Rotary Cyclone Recovery - CAT Series

- Powder Coating Booth with Cartridge Recovery - OXYGEN Series

- After Filter Suitable For Cyclone & Rotary Cyclone Recoveries

Sievers

Special Powder Coating Equipment

- PTFE- ECTFE Powder Coating Gun

- Pipe Coating Equipment

- Rebar Coating Equipment

- Compact Gun & Booth for Powder & Resin Manufacturers

- Fast Colour Change Gun For Powder & Resin Manufacturers

- Powder Coating Equipment For Fluorescent Penetrant Inspection Process

- Powder Coating Machine to spray Boron Nitride powder for aluminum extrusion application

- Talc Powder Spray System For Green Rubber Tubes

Attachments

X